Only logged in customers who have purchased this product may leave a review.

Industrial Mechatronic System – Drilling and milling sub-system

$0.00

ABOUT THIS PRODUCT:

IMS Industrial mechatronics system

The “Industrial Mechatronics System” (IMS) allows industrial-type automated installations of varying degrees of complexity

to be modelled. IMS is a modular system that can be employed with great flexibility and the modular design also makes it

easily extensible. This means that systems can be put together taking into account students’ previous knowledge and can

be expanded as they learn more.

- Use of authentic industrial components means that trainees can get to grips with work more quickly after completing their training

- It is possible to handle a dual training scenario using only a single system: educational by integrating the system with UniTrain/multimedia courses or industrial, involving connection to an industrial PLC system

- Small projects can be conducted using IMS individual components especially the conveyor belt and sub-systems.

- The possibility of connecting directly to PROFIBUS means less wiring and a more easily understood structure

- Trainees understand the functional processes and the interplay between signalling states quicker thanks to the possibility of reading I/O signals directly from the system. Tapping into signal states via an external control system is not impossible but the status LEDs make it unnecessary

- More complex tasks can be assembled using IMS sub-systems. These involve combinations of individual IMS components to provide additional functionalities.

- The fact that various parts of the system can easily be separated from it means that it is no problem to construct customised lessons

- Complete production lines with carrier return systems can be put together using IMS sub-systems. Multiple-layered projects constructed in this way require a fundamental knowledge of IMS sub-systems.

Mechatronics Sub-Systems with UniTrain

All IMS sub-systems are composed of several individual IMS components and are accompanied by UniTrain courses. As an

alternative, they can of course all be connected to any programmable logic controller by means of standard connectors. Before IMS sub-systems are connected in larger installations, the requisite knowledge and skills should be learned with the aid of multi-media UniTrain courses.

- IMS sub-systems with UniTrain courses: we strongly recommend undertaking an introduction to the IMS sub-systems with the aid of the accompanying UniTrain courses. These explain the sub-systems clearly, understandably and in detail and demonstrate how they can be programmed. Supplied with the course is a PLC system that can automatically control the sub-systems or, subsequently, more complex installations as well. This makes it very simple to step up to the Siemens programmable logic control system afterwards.

Training objectives for sub-systems:

- Analysis of functional relationships

- Set-up and adjustment of sensors

- Introduction to electrical and pneumatic function modules

- Configuration of mechatronics sub-systems

- Investigation of the flow of energy and information

- PLC programming

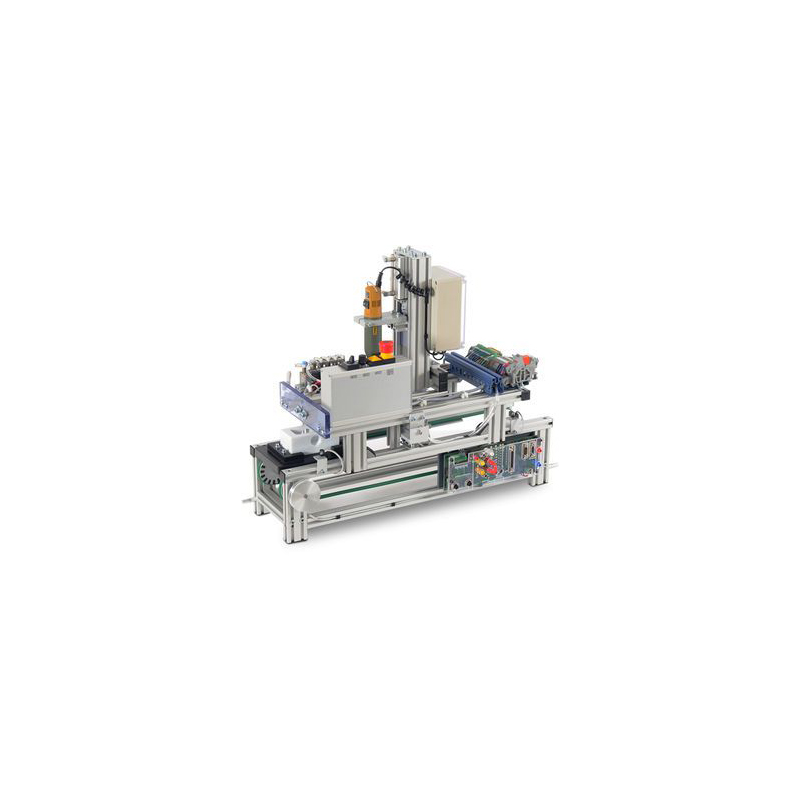

IMS 13 Drilling and milling sub-system

A workpiece carrier with the bottom part of a workpiece is placed on the conveyor belt. The drilling and cutting station has

a controllable cutting head which reams out the internal contour of the workpiece section. The cutting head can be moved

in three axes in order to work on the component. Afterwards the workpiece carrier with its workpiece is moved to the end

of the conveyor belt to be passed on to the next sub-system.

This Package Contains:

Item 1 – Course Mechatronic Stations CO4204-3K

Includes:

Experiment board PLC trainer

- CPU with PLC functionality

- 8 digital inputs with simulation switches and status LEDs

- 8 digital outputs with status LED connected to 2 mm sockets

- 8 analog inputs with 10-bit resolution, of which 4 inputs 0-10 V and 4 inputs 4-20 mA

- 4 analog outputs, of which 2 outputs 0-10 V and 2 outputs 4-20 mA

- 1 potentiometer for simulation of an analog 0-10 V signal via 2 mm sockets

- 1 potentiometer for simulation of an analog 4-20 mA signal via 2 mm sockets

- LAN switch with three connection terminals

- 9-pin D-Sub socket with connection to digital inputs and outputs of the PLC

- 25-pin D-Sub socket with connection to digital inputs and outputs of the PLC

- Status LED of the PLC

- Browser and course software

Topics:

Projects for Transport system IMS1.2 and for stations:

- IMS3 Sorting, IMS4 Assembly, IMS5 Processing, IMS6 Testing, IMS7 Handling, IMS8 Storage, IMS13 Drilling and Milling

- Experiments: Inching mode, Inching mode with end limit, Analog values, Positioning, Speed control, Blinking, Function blocks

- Topics for all stations:

- Pin assignment

- Hardware setup

- Sequence control

- Watchdog

- Additionally, for Storage:

- Store and remove Z-axis

- Store and remove X-axis

- Course duration: 24 h approx.

Item 2 – Drilling and milling station LM9688

Drilling and milling machine to mill the recess in the bottom part of an IMS® workpiece. The milling machine can be controlled with two different feeds.

- Milling head

- Milling spindle, 5,000 – 20,000 rpm, controlled by 0…10 V internally or externally

- Potentiometer for internal speed setting

- Position sensor

- Clamping cylinder

- Valve block 5 x 4/2-way solenoid valves

- Milling feed cylinder, Z-axis

- Milling feed cylinder, x-axis

- Milling feed cylinder, Y-axis

- Stop cylinder, double-acting

- Control console with the following components:

- Selector switch for speed setting

- Potentiometer

- Indicator light

- Emergency stop with indicator light

- PLC port via 25-pin SUB-D connector

- PLC requirements: 8 x digital outputs, 11 x digital inputs, 1 x analog output for speed (can also be controlled via potentiometer)

Item 3 – Double conveyor belt segment, 24 V motor LM9606

Basic mechatronics module driven by a variable speed 24-V geared motor and complete with end-limit sensors and integrated PROFIBUS DP slave. Designed for basic experiments on a conveyor system or for incorporation into a complex mechatronics system for controlling the flow of materials. The conveyor belt conveys work pieces on carriers and can be used to link individual sub-systems. It is designed for connection to a PLC control system. It can be combined with other conveyor belts, ‘curve’ units or transfer junctions. IMS stations can be connected directly to the belt and jointly controlled via PROFIBUS.

- Length = 600 mm/23,6″, width = 160 mm/6,3″,

- belt width = 120 mm/4,7″

- Geared motor, 24 V DC

- Pulse width modulation system for controlling belt at various speeds

- Continuous speed adjustment via potentiometer or analogue input, 0-10 V

- Manual switches for movement to left or right

- 2 inductive end-limit sensors

- 2 x M12 interfaces for additional actuators/sensors

- Sockets for emergency shut-off circuit (disconnection of all voltage to output modules)

- External power supply via 4-mm safety sockets or coaxial power connector

- 9-pin SUB-D connector for contactors, LOGO! or PLC

- Incremental encoder disc for detecting position and speed via optical sensors

- Visualisation as interactive 3D model in IMS-virtual database

- Control requirements: 4 x digital inputs, 3 x digital outputs

PROFIBUS DP slave module:

- Address range: 16 digital input/outputs

- PROFIBUS DP connector: 9-pin DSUB socket

- Rotary switch for setting address

- Transmission rates of up to 6 MB/s

- GSD file for use with control software (e.g.: STEP7)

- 25-pin DSUB socket for connecting IMS station

- Output current: 500 mA (total current: 1 A)

- Variable speed control of conveyor belt via PROFIBUS

Item 4 – Workpiece transport pallet LM9520

Pallets for carrying and transporting workpieces on conveyor belts. The pallet has a 4-bit identification code.

- Length = 180 mm/7,1″, width = 119 mm/4,7″,

- height = 15 mm/0,6″

- Position sensor

- 4-bit identification code

Item 5 – Workpiece, top section, white LM9521

Material: plastic

- Colour: white

- Magnetic clip for attachment to bottom section

- Spring-loaded bearing for attaching bolt

- Dimensions (L x W x H): (100 x 50 x 40) mm / 3,9″ x 1,97″ x 1,57″

Item 6 – Workpiece, bottom section, black LM9525

Material: plastic

- Colour: black

- Magnetic clip for attachment to top section

- Dimensions (L x W x H): (100 x 50 x 40) mm / 3,9″ x 1,97″ x 1,57″

Item 7 – 25-pin serial interface cable, Sub-D plug/socket LM9061

25 pin Sub-D connection cable

- Length: 2 m

- Connection: 25-pin plug / 25-pin socket

- Pin assignment: 1:1

Item 8 – Serial interface cable 9/9 pole LM9040

9-pin SUB-D cable

- Length: 2 m

- Connector: 9-pin plug/9-pin socket

- Pin assignment: 1:1

Reviews

There are no reviews yet.